Posted by Joe S. on Sep 4th 2025

The History of 3D-Printed Suppressors

Preamble

The compilation of the history of printed suppressors below is intended to be a living document. We are happy to add notes and corrections and hope that you, the readers, will collaborate with us to make this as accurate as possible. The early days of suppressor development in the printed space were often not that widely discussed but the history behind the designs serves as an important set of milestones that helped us evolve to where we are in the current state of the art.

The History of 3D-Printed Suppressors

3D printing has transformed countless industries, from aerospace to medical implants, and firearms are no exception. Among the most controversial applications is the development of 3D-printed suppressors, devices designed to reduce the sound signature of a firearm. While traditional suppressors have been manufactured from metal using machining, welding, and other industrial processes, 3D printing has introduced both new opportunities and new concerns.

Early Experiments (2000s)

The earliest mentions of 3D-printed suppressors appeared in the early 2000s, shortly after the consumer 3D printing boom. Hobbyists began experimenting with polymer-based suppressor baffles and sleeves using desktop printers. These first designs were rudimentary, often failing after only a few rounds due to heat, pressure, and erosion. Still, they demonstrated the feasibility of additive manufacturing for firearms accessories.

One of the earliest widely circulated projects was the “Shuty” pistol builds and experimental suppressors shared on forums and file-sharing platforms around 2012–2014. Around the same time, defense companies also began quietly researching metal additive manufacturing. Some firms in Europe and Oceania publicized that they had successfully printed monolithic titanium suppressor components, proving the concept could work beyond plastic prototypes.

Refinements and Online Sharing

By the mid-2010s, 3D printing technology had improved. Stronger materials like nylon blends, reinforced polymers, and sintered metals gave home experimenters more durability. Designers began sharing CAD files online, leading to an exchange of new baffle geometries, mounting systems, and hybrid polymer-metal builds.

Entry of Professional Manufacturing

While hobbyist designs gained attention, established suppressor manufacturers also began exploring 3D printing for commercial products. Metal additive manufacturing processes allowed the creation of complex internal geometries such as lattice structures and intricate baffle shapes that would be impossible or prohibitively expensive to make with traditional machining.

From the early 2000’s up through the 2020s, several companies introduced commercial 3D-printed suppressors made from Inconel, titanium, or stainless steel. These suppressors weren’t just proof of concept, they were market-ready, durable, and often outperformed traditionally machined models in terms of strength-to-weight ratio.

Timeline of Key Milestones

- 2008-2010: Advanced manufacturing methods are being explored in the development of baffle design and suppressor construction.

-

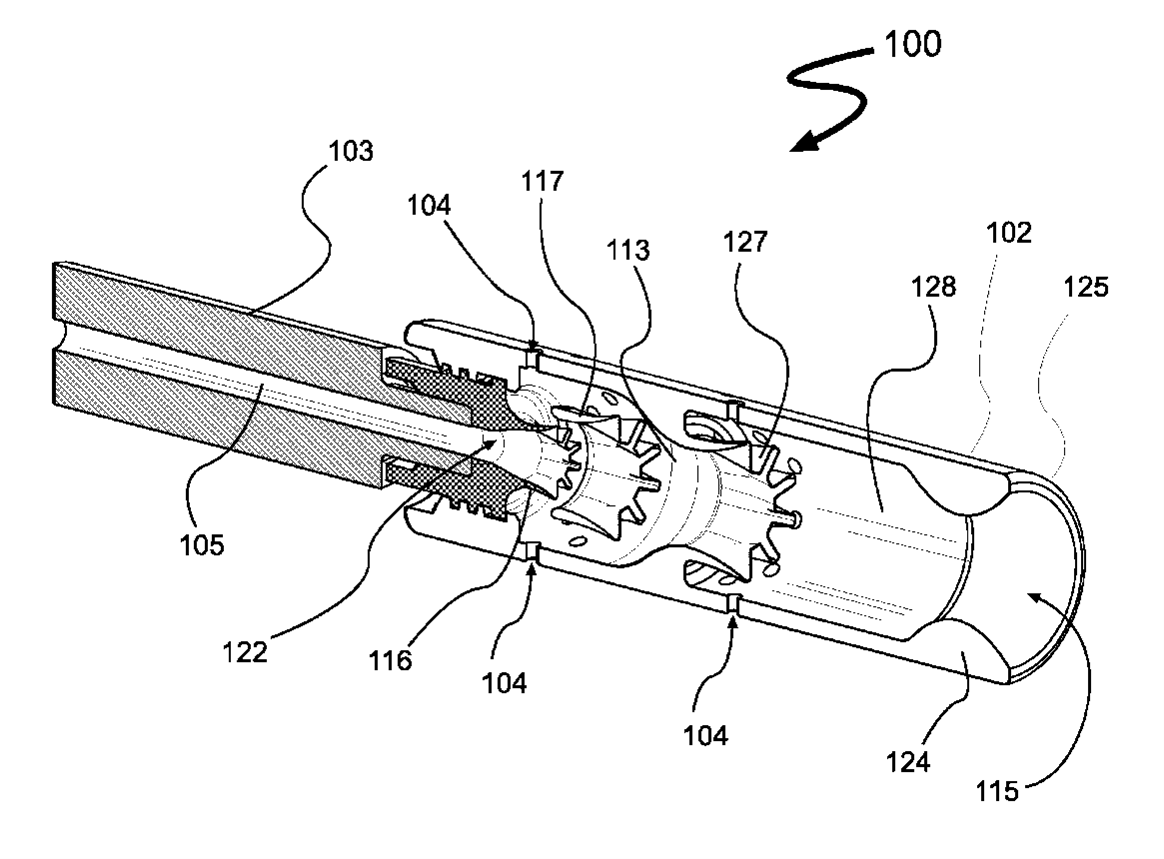

- September 17, 2008: Flodesign, Inc. develops a monolithic suppressor (Pat. 8322266) utilizing early DMLS manufacturing methods to produce a novel suppressor for the USMC under a NAVY SBIR.

-

- 2010: Delta P Design releases the Brevis line of compact printed monolithic suppressors

- 2010–2012: Hobbyists begin experimenting with plastic suppressor prototypes on desktop 3D printers. Early commercial development of commercial printed suppressors.

-

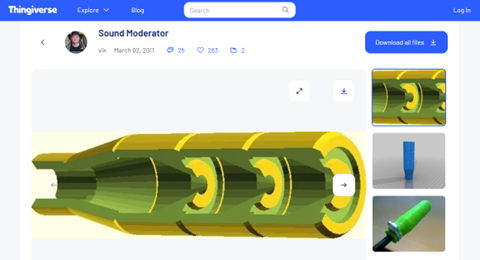

- March 02,2011: User Vik publicly posts a monolithic “Sound Moderator” on Thingiverse.com depicting a seamless monolithic noise suppression device for use with a firearm with a plurality of baffles within the assembly.

-

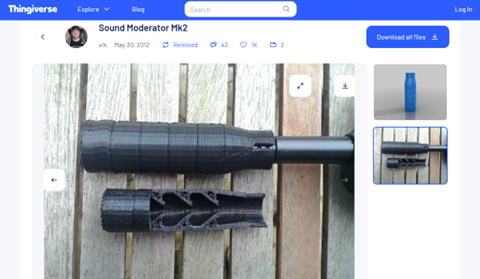

- May 30,2012: User Vik posts a monolithic “Sound Moderator Mk2” on Thingiverse.com for public consumption as an evolution of his earlier design

- December 2012: Oceania Defence Ltd, begins manufacturing partnership with Titanium Industry Development Association (TIDA)

- 2013–2014: Online forums circulate the first open-source designs, including projects like the “Shuty” pistol builds with 3D-printed components.

- 2014–2015: Reports emerge of defense companies and private firms experimenting with metal 3D printing for suppressor parts.

- 2014: Delta P Design® introduces the BrevisII and debuts is at shot show 2015

- 2016–2018: Strengthened polymers, fiber-reinforced filaments, and hybrid metal sleeves allow hobbyist suppressors to survive more than just a few rounds.

- 2017–2019: Established manufacturers begin unveiling prototypes of fully metal 3D-printed suppressors using titanium and Inconel.

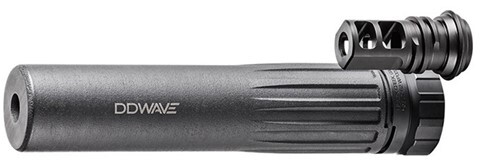

- 2017: Daniel Defense® launches the DD Wave suppressor

- 2019–2021: Several companies release commercially available 3D-printed suppressors, emphasizing lightweight builds and unique internal structures.

- August 2020: Sig Sauer® is slated to release a MODX® 9mm suppressor featuring a 3D printed baffle stack

- 2022–Present: Additive manufacturing becomes mainstream in the suppressor industry, with companies using it to create optimized designs that outperform traditional machining in efficiency and durability.

- June 2022:Oss Mission® now known as Huxwrx® (huxwrx.com) releases a suppressor utilizing their novel flow through geometry previously machined into their cores as a fully printed system that traps and redirects gasses forward of the shooter

The Present Landscape

Today, 3D-printed suppressors fall into two distinct categories:

- Hobbyist/Home Builds: Ranging from polymer experiments to hybrid metal-sleeved versions, these remain controversial and legally complex. They’re often used as testbeds for new ideas rather than long-lasting tools.

- Commercial Additive Manufacturing: Suppressor companies now regularly use 3D printing to push the boundaries of design. Modern printed suppressors are lighter, more efficient, and better tailored to specific calibers and applications.

Looking Ahead

The history of 3D-printed suppressors illustrates how quickly firearm technology evolves when it intersects with broader innovation. While regulation, safety, and ethical considerations will continue to shape their development, the trajectory is clear: additive manufacturing has carved out a permanent role in the suppressor industry.

As 3D printing continues to advance with higher-temperature polymers, better metal powders, and more affordable machines, the next generation of suppressors may look radically different from the designs of today.